Equipments & Facilities

- All

- Electrical Characterization

- Magnetic Characterization

- Mechanical Characterization

- Sample Preparation

- Thermal Characterization

VSM / Microsense

- Range: -170ºC to 1300ºC ; Maximum field 2.2 Tesla

- Ar, N2

Hysteresis loops/magnetoelectric measurements (up to 1000 V) /time-dependent measurements

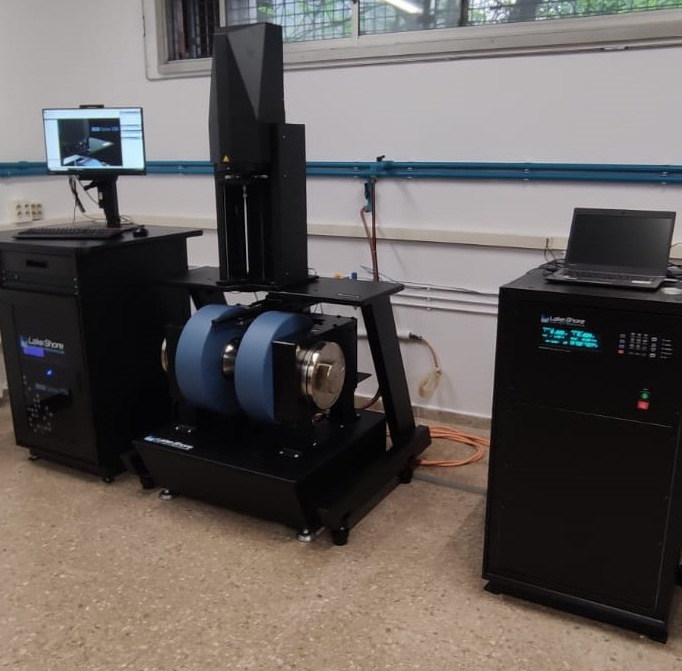

VSM / Lakeshore

- T range: –170ºC to 1300ºC

- Maximum field 3.5 Tesla in Ar, N2

- Fast acquisition rate (30 ms/point)

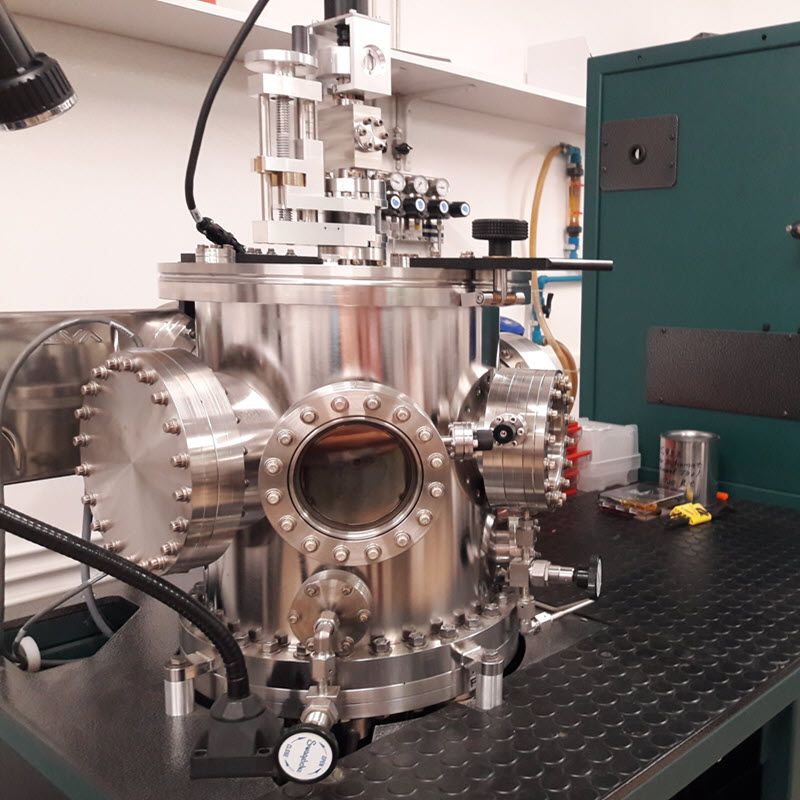

Sputtering system / AJA international

- Possibility to do co-sputtering (to grow alloy films)

- Ar, reactive sputtering (for oxides and nitrides)

RF, DC generators for magnetron sputtering

High-T sputtering / AJA

- Possibility to do co-sputtering (to grow alloy films)

- Reactive sputtering (for oxides and nitrides)

- Automatized RF, DC generators for magnetron sputtering

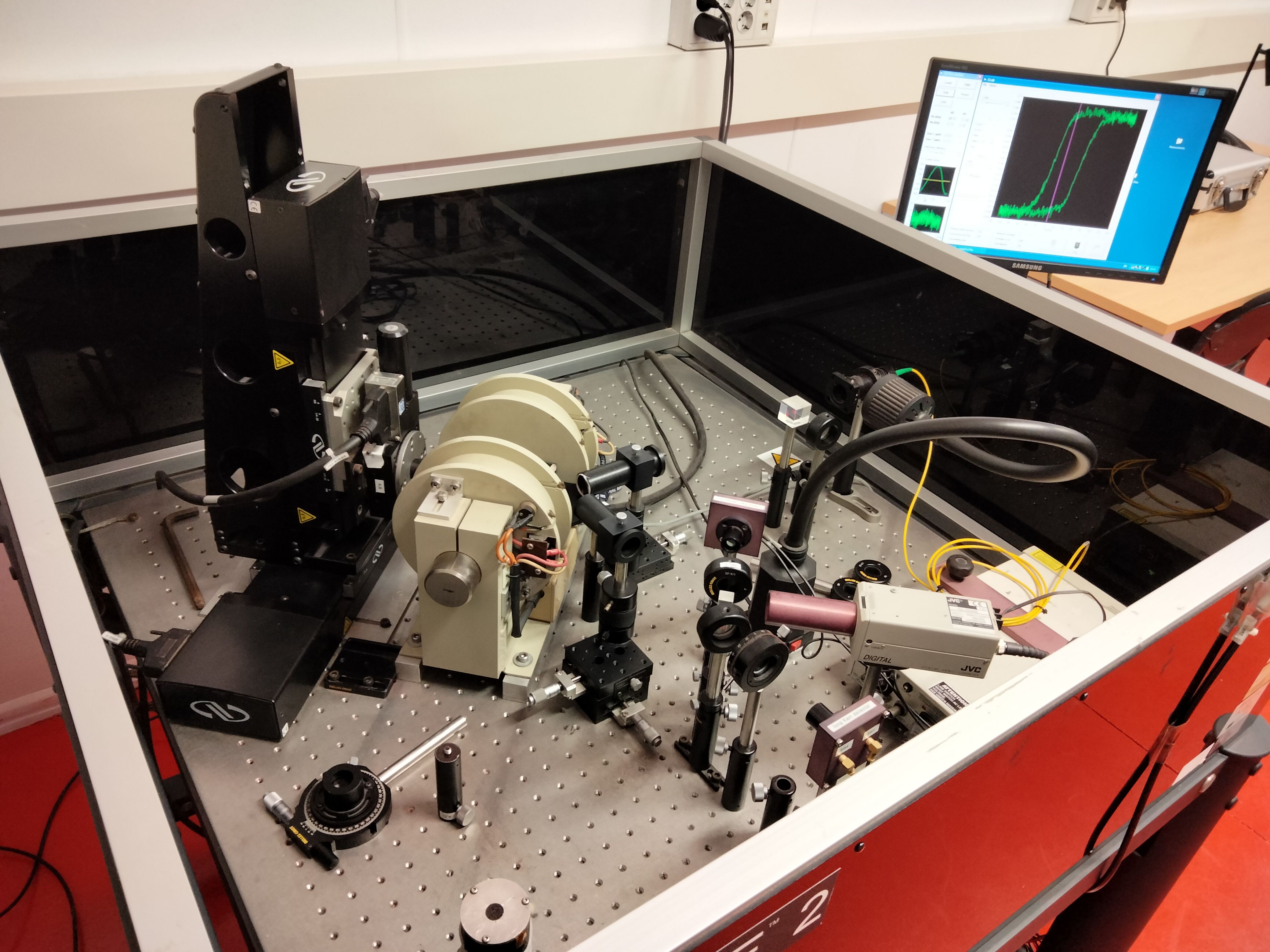

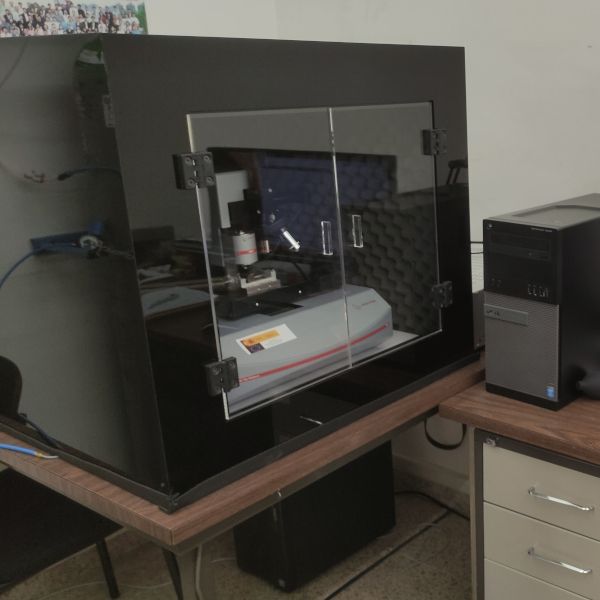

Magneto-optic Kerr Effect / Nanomoke Durham

- From 10 K to 600 K

- Maximum magnetic field 0.5 T

- Dipolar and Quadrupolar magnet

Longitudinal, transversal and polar MOKE configurations

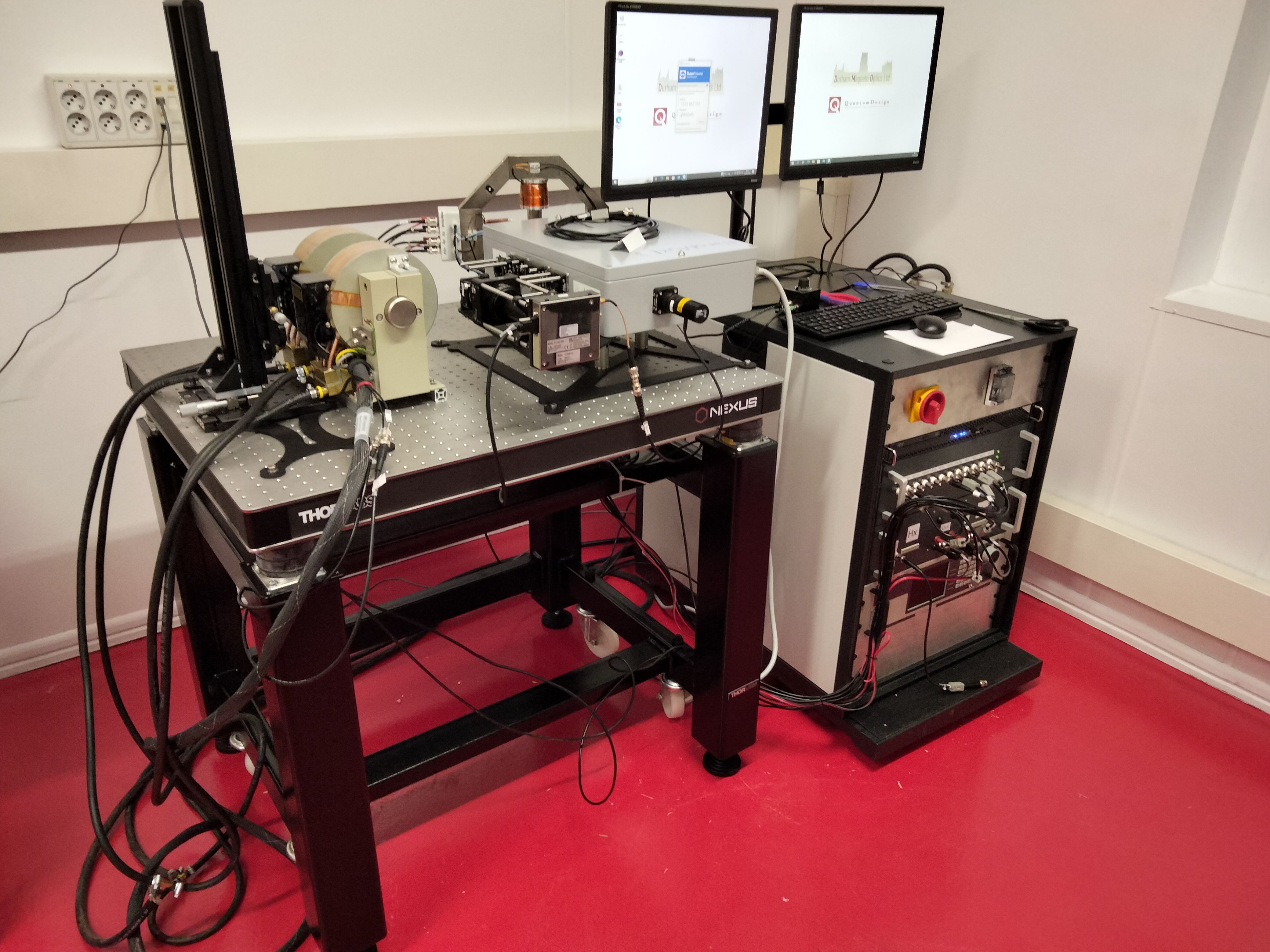

Magneto-optic Kerr Effect / Nanomoke 3 Durham

- Fast acquisition rate (100 ms)

- Maximum magnetic field 2 T (in-plane and out-of-plane)

- Dipolar and Quadrupolar magnet

Longitudinal, transversal and polar MOKE configurations

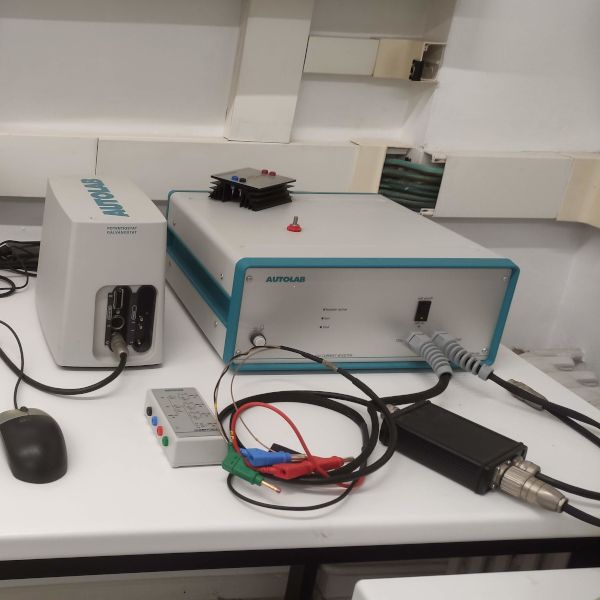

PGSTAT 302N / Potentiostat-galvanostat

- Equipped with ECD and FRA modules

Used to grow materials, mostly metals and alloys of varying dimensionality, and for electrocatalysis and corrosion experiments.

PGSTAT204 / Potentiostat-galvanostat

- With spectroelectrochemical module and booster

Used to grow materials, mostly metals and alloys of varying dimensionality, and for electrocatalysis and corrosion experiments

Coater 5 AC / Idlab

- 10ºC - 40ºC

- Relative humidity range: 10% to 90% RH.

Preparation of thin/porous layers by dipping solid substrates into the solution

150i / Polos

Spin process applications of wafers and other substrates

NHT2 / Anton Paar

- Load-displacement curves, range: 0.5 – 500 mN.

For precise determination of mechanical properties (hardness or elastic modulus) of thin films, coatings, or patterned structures

UMIS

- Finite element modelling

- Nanoindentation

For precise determination of mechanical properties (hardness or elastic modulus) of thin films, coatings, or patterned structures.

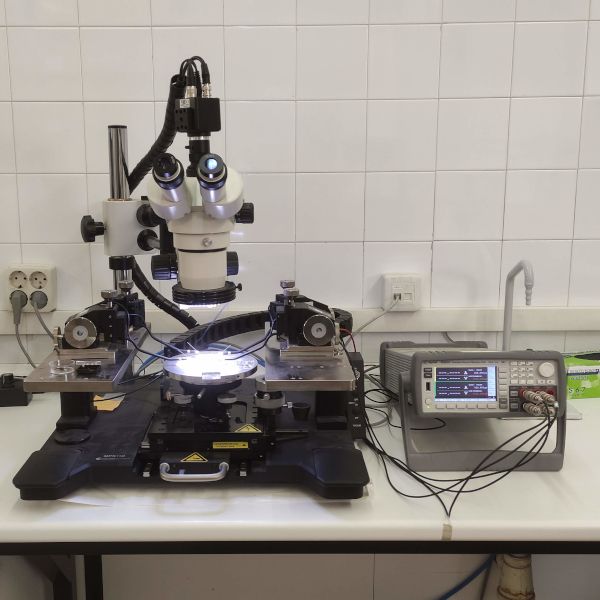

MPS150 / Cascade Microtech

Manual probe station used for four-point resistance measurements

NanoIndenter XP/ MTS

- Nanoindentation, CSM, scratch test

For precise determination of mechanical properties (hardness or elastic modulus) of thin films, coatings, or patterned structures

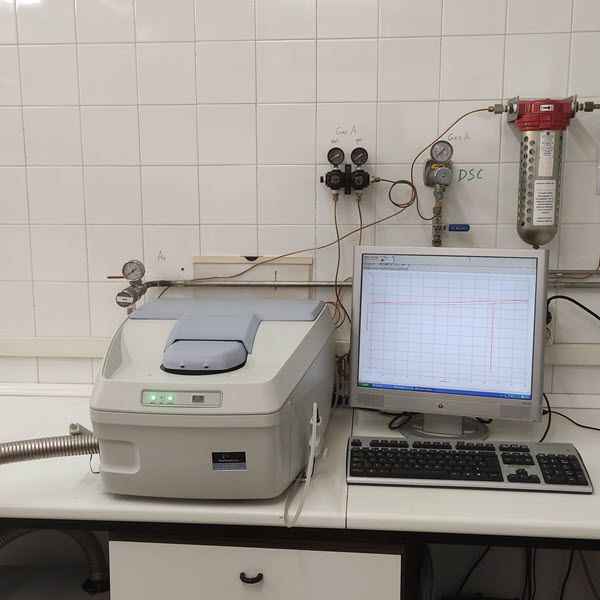

DSC8000 / Perkin Elmer

- Range: -50ºC to 750ºC

- Ar, Air

Modulated temperature-DSC

DSC 7 / Perkin Elmer

- Range: 0ºC to 850ºC

- Ar, Air

To study the thermal properties of materials, including phase transformations.

TGA7 / Perkin Elmer

- Range: 0ºC to 900ºC

- Ar, Air

High Vacum system / Thermolab

- Range: 20ºC to 1500ºC

Heat Theatments under vacum

MTS 653

- Range: 20ºC to 1200ºC

- Ar, Air,N2, H2, Ar+5%H2

High Vacum

Arc Melter MAM-1 / Buehler

- Ar, N2

Used to prepare metallic glasses

Glove box / Mbrawn

- Ar < 1 ppm O2 & H2O

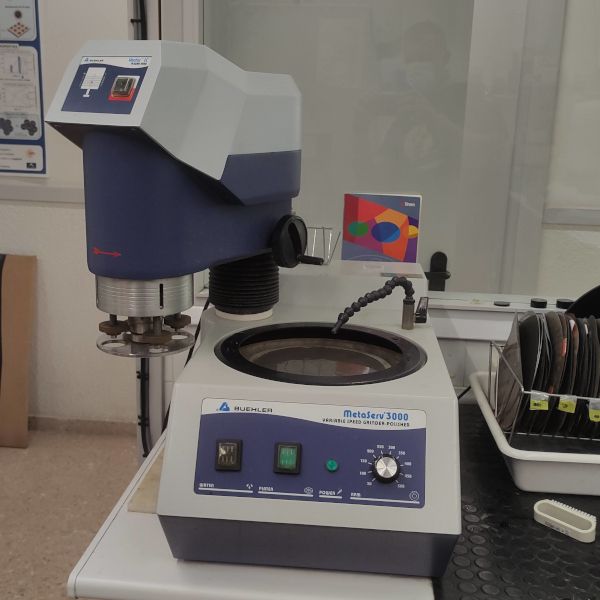

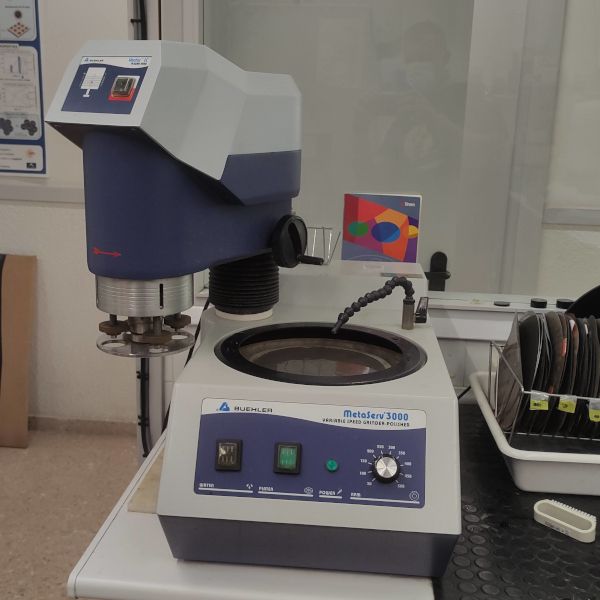

Metaserv 3000 / Buehler

Surface polishing down to 0,05um

Isomet 100 / Buehler

PNEUMET II / Buehler

Speex 8000

- 1-5g

- Ar, air

Used for mixing, homogenising and reducing particle size (mechanical alloying)

Pulverisette 5 / Fritsch

- 5-20g

- Ar, Air, H2

Used for mixing, homogenising and reducing particle size (mechanical alloying)

FV-700 / Future-tech CORP

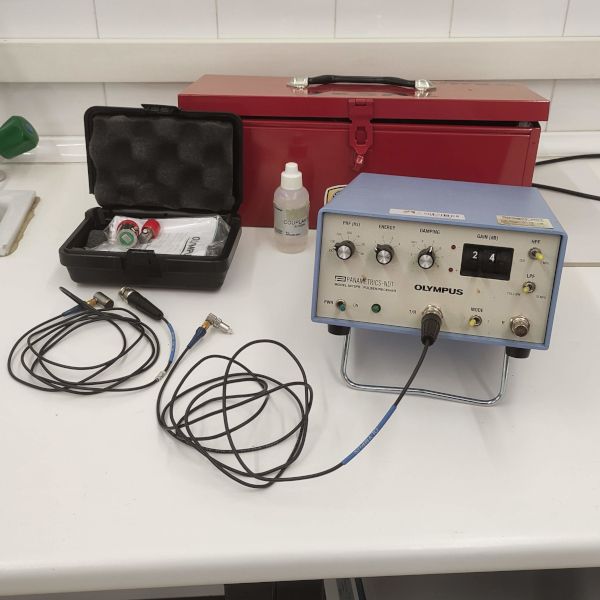

5072PR / Olympus

Non-destructive technique for assessement of elastic constants

DS 95-50 Dualscope® / DME

- To evaluate surface roughness of thin films (AFM)

- To observe magnetic domain patterns at remanence (MFM)

Scan window 20 micron x 20 micron

TGM7 / Perkin Elemer

- Range: 0ºC to 900ºC

- Ar, Air

Atomic Force Microscopy / Asylum

- In-situ magnetic fields

- High-voltage

- Environmental AFM and liquid cell

Scanning probe microscopy for multi-purpose surface characterization.

-

Other UAB Facilities

- Chemical ICP analysis

- Transmission electron microscopy

- Scanning electron microscopy

- X Ray diffraction (RT up to 700K)

- Cytotoxicity and Cell Adhesion studies (Department of Cellular Biology, Physiology and Immunology)

- Magneto-optic Kerr effect (MOKE) setup.

- Superconducting quantum interference device (SQUID)